Product Description :

Single Drum Magnetic Separator : Single Drum Magnetic Separator is most useful for separating tramp iron from non magnetic material processed in bulk quantity, for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. These are widely used in all the processing industry for separation of iron contamination from Minerals, Chemicals, Food, Flour, Plastics, Grains, Sand, Cement, Fertilizers, Abrasives, Glass, Slag, Ores, Rock, Refractory and many other products.

Double Drum Magnetic Separator : Double Drum Magnetic Separators are available for highest purity. The material passes through the magnet twice in Double Drum type Machine. These are widely used for separation of iron contamination from Minerals, Chemicals, Refractory and many other products.

Size Range :

The Permanent Drum Separators are available in standard drum diameters of 300 mm. 400 mm, 450 mm, 500 mm, 600 mm, 800 mm Drum width range from 300 mm to 1500 mm. Other sizes can be made as special to your requirement. the larger the diameter and width of the drum the greater is the volume of material which can be handled.

Magnetic Materials :

Magnetic separators are offered with two different type of magnets.

Ferrite Magnet :

The magnetic separator with ceramic magnet are useful for the application where free and larger iron particles are to be separated. The average magnetic intensity on the magnetic drum surface will be 1500-2000 Gauss.

Rare Earth Magnet :

The magnetic separator with high intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnets are useful for removing magnetic contamination with low magnetic properties and fine iron particles are to be separated. The average magnetic intensity on the drum surface will be 3500 – 5500 Gauss.

The permanent Magnetic Drum consists of stationery permanent Magnetic assembly having uniform and everlasting Magnetic field across the entire width of the drum, which is effective over approximately half the drum circumferences as shown in fig.

Drum shell made of non magnetic stainless steel revolves around the magnetic filed. As the material fed evenly from the chute falls over the drum, powerful magnetic, field attract & holds ferrous particles to the revolving shell. As the revolving shell carries the iron particles through the stationery magnetic field, the non magnetic material falls freely from the shell while ferrous particles are firmly held until carried beyond divider and out of magnetic field.

The strength of the permanent magnetic drum is guaranteed to be greater than corresponding electromagnetic Drum. The permanent magnets used are everlasting magnets and its strength does not diminish during normal use and can be used through out the life of the installation.

Salient Features :

- Drum consists of High Powered Anisotropic Permanent Magnet.

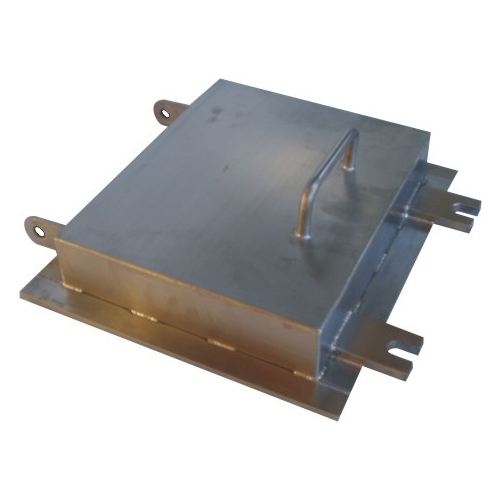

- Strong & Rugged Construction.

- Automatic separation of ferrous material.

- Completely Enclosed design to avoid Dusting and Pollution.

| Model No. | Capacity tones per Hours | Drum Size (Dia mm) | Length mm |

|---|---|---|---|

| BM-740-SDS | 1.5 | 400 | 600 |

| BM-742-SDS | 3.0 | 550 | 550 |

| BM-744-SDS | 7.0 | 650 | 1100 |